A Guide to Emergency Lighting - Introduction

WHAT IS EMERGENCY LIGHTING?

Emergency lighting is lighting that automatically comes into operation when the mains power supply to the normal lighting fails.

DO I NEED EMERGENCY LIGHTING?

Premises that would normally require emergency lighting include: shops, offices, factories, warehouses, schools, hospitals, the public (landlord) areas of residential blocks, railway stations & airport termini, carparks, leisure centres, pubs, theatres and places of worship.

Emergency lighting is required wherever the public has access to a building or where people are employed.

Premises that do not normally require emergency lighting are individual houses and the privately occupied areas (flats and maisonettes) within larger residential blocks.

Emergency lighting is not required in private residential property that does not have public access.

Because emergency lighting concerns the safety of the public and employees it is heavily regulated. Several regulations, laws and standards define when and where it is required, the light levels that must be provided and how it should be maintained and tested.

For more information, read here:

To understand the regulations related to emergency lighting: What are the regulations & standards governing emergency lighting?

To understand about the different types of emergency lighting: What are the different types of emergency lighting fixture ?

To understand the process of emergency lighting design: Emergency Lighting Design

To understand emergency lighting testing: Emergency Lighting Testing

For FAQs: Frequently Asked Questions

WHAT ARE THE REGULATIONS & STANDARDS GOVERNING EMERGENCY LIGHTING?

Below is a summary of the most important regulations and standards affecting emergency lighting.

- The Regulatory Reform (Fire Safety) Order 2005 (or RRO). This applies to England and Wales, but equivalent legislation is in place in Scotland and Northern Ireland. It is very broad in its scope.

- The RRO applies to all premises except for:

- Domestic premises

- Offshore installations

- Fields, woods or other land (provided they are away from an undertaking’s main premises)

- Aircraft, locomotives or rolling stock, trailers or semi-trailers used as a means of transport or a vehicle for which a licence is in force

- Mines

- Boreholes

- The RRO applies regardless of the ownership of a building, so the public sector, private sector, individuals, charities and trusts all fall within its scope.

- The RRO introduces the concept of the “Responsible Person”. In Scotland this is the “Duty Holder” and in Norther Ireland it is the “Appropriate Person”. Their responsibilities are considerable, but so far as emergency lighting is concerned they are required to ensure that:

- Emergency exits and routes are indicated by signs, and

- Emergency exits and routes requiring illumination are provided with emergency lighting of adequate intensity in the case of failure of their normal lighting.

- Emergency lighting is subject to a suitable system of maintenance

It will be clear from the above that for the “Responsible Person” to discharge their duties it is necessary that there are standards to follow concerning the design of an emergency lighting installation, the construction and performance of the emergency lighting fixtures themselves and the testing of the installation.

- Building Regulations 2010 Fire Safety Approved Document B. This document (download here )mandates the use of escape lighting in almost all buildings and situations except for private residential premises. See table 5.1 and paragraphs 5.25 – 5.27. This document also states that escape lighting must comply with BS 5266-1 and that exit signs must comply with BS 5499-4.

- BS 5266-1. Emergency lighting – Part 1: Code of practice for the emergency lighting of premises. Some of the key provisions of BS 5266-1 are as follows:

- Minimum lux levels for emergency lighting. BS 5266-1 defines the minimum lux levels that should be provided as follows:

- Defined escape routes should be illuminated to a level of not less than 1 lux along their centre line at floor level.

- Open areas should be illuminated to a level of not less than 0.5 lux at floor level.

- High risk task areas should be illuminated to a level of not less than 10% of the average of the normal lighting provided at that point.

- The location of emergency light fittings should include. BS 5266-1 advises where emergency lighting should be placed.

- Near each exit door intended to be used in an emergency

- Near stairs, so that each flight receives direct light

- Near any change in level

- Externally illuminated escape route signs and other safety signs needing illumination under emergency lighting conditions

- At each change of direction

- At each intersection of corridors

- Near each final exit to the outside of the building and to a place of safety

- Near each first aid post

- Near each piece of fire-fighting equipment and call point

- Near escape equipment provided for disabled people

- Near refuges and call points including two-way communication systems and disabled toilet alarm call positions

- Near manual release controls that release electronically locked doors

- Outside the building close to each final exit

- In toilets used by disabled people and multiple closet facilities

- All motor generator rooms, plant rooms, control rooms and switch rooms

- Pedestrian escape routes from covered and multi-storey car parks

- Emergency lighting duration. BS 5266-1 states that emergency light fittings should be able to operate for 3 hours following a mains power failure. 1 hour is also permissible, but only if the building will be evacuated immediately in the event of a power failure and not re-occupied till the batteries have been fully recharged.

- Emergency lighting testing. BS5266-1 defines the testing that should be performed on an emergency lighting system as follows:

- A brief functional test at least once each month

- A full duration test at least every year

- A visual inspection at least every year

- BS 5266-1 also advises that records of all tests and repairs should be kept in a log book.

- BS 5499-4. Code of practice for escape route signing. This standard gives recommendations for the selection and use of escape route signs conforming to ISO7010. Some of the key provisions of BS 5499-4 include:

- Signage design. BS 5499-4 mandates the use of legends and directional arrows, all defined in BS EN ISO 7010. These are widely known as ISO7010 legends and are easily distinguished by their use of an image of a man running through a door. BS 5499-4:2013 also mandates the use of supplementary text, such as “Exit” or “Fire exit” alongside the legend and arrow. However, the EC safety signs directive (92/58/EC) adopted a pictogram-only approach (no text). For a summary of the signage designs that are currently approved for use in the UK

- Please check “What type/style of emergency exit sign are allowed in the UK?”

- Signage location. BS 5499-4 advises where signs should be located and the principles that should be adopted to ensure that they are appropriately sited.

- Signage mounting heights. BS 5499-4 advises that signs should be mounted consistently and conspicuously and recommends specific mounting heights that should be adopted wherever practical.

- Use of directional arrows. BS 5499-4 makes it clear that “straight ahead” is to be indicated with an up-arrow.

- Sign size and viewing distance. BS 5499-4 defines the maximum viewing distance for an illuminated sign based on its luminance measured in cd/m². When NVC Lighting states the maximum viewing distance of an illuminated emergency exit sign it is in relation to BS 5499-4.

- BS 5499-4 makes frequent reference to other standards. In particular, BS 5499-4 refers to:

- BS 5266-1 for the inspection, testing and maintenance of exit signs

- BS EN 60598-2-22 for all constructional aspects of emergency lighting signage

- BS ISO 3864-1, -3, -4 for detailed aspects of signage design such as colours, graphics and text

WHAT ARE THE DIFFERENT TYPES OF EMERGENCY LIGHTING FIXTURE?

Emergency lighting fixtures can be classified in at least two ways:

- How it works

- Self-contained

- Maintained & non-maintained

- Central battery

- Maintained & non-maintained

- Its function

- Escape lighting

- Open area & signage

- Standby lighting

- High risk task lighting

Classified according to how they work there are two main types of emergency lighting fixture:

- Self-contained emergency lighting fixtures have their own re-chargeable batteries and an associated re-charging circuit built in. When mains power fails the batteries automatically provide the power required to operate the fixture. Because it is necessary for the batteries to be kept at or near to a 100% fully-charged state it is mandatory that self-contained emergency lighting fixtures are connected to a permanent (un-switched) live supply .

- Please check How should emergency lighting be tested and wired? . Self-contained emergency lighting fixtures account for about 80% of the UK emergency lighting market and are suitable for many types and sizes of building.

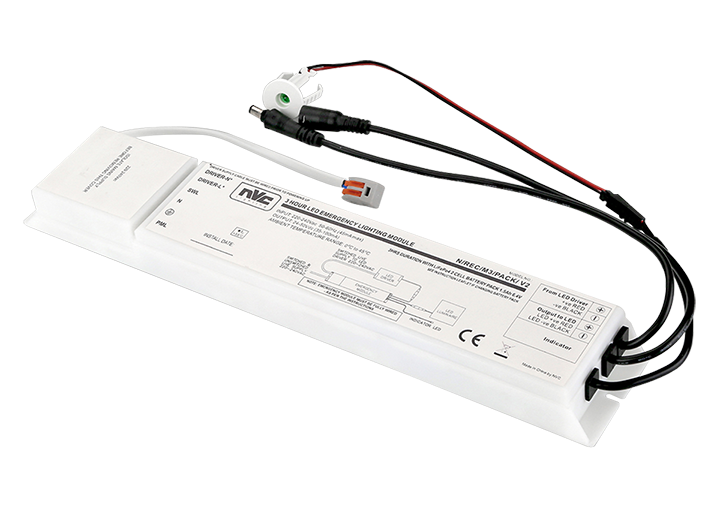

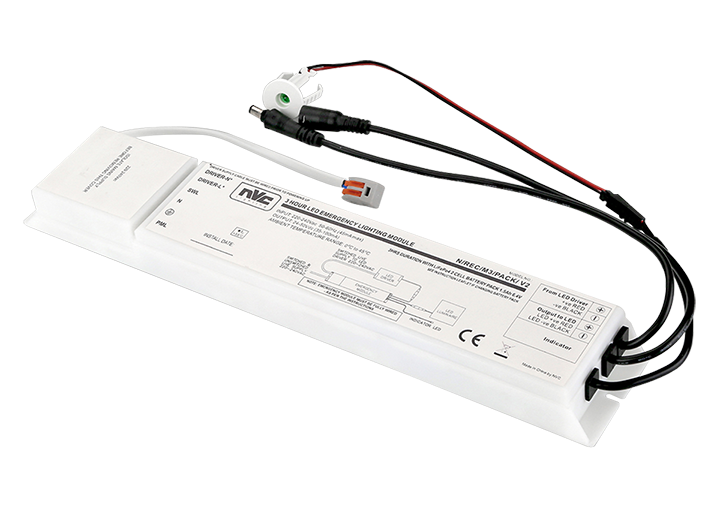

A typical emergency conversion kit. This is used to convert a normal mains powered light fitting, such as an LED panel, into an LED panel that will function as a self-contained emergency fitting if there is a power failure.

The plastic enclosure contains the necessary electronics and the batteries to power the fitting for 3 hours.

- Central battery emergency lighting fittings are connected, via special fire-resistant cable, to a central battery that will deliver the required power when mains power fails. Central battery systems account for about 20% of the UK emergency lighting market and are mostly confined to large buildings and estates such as office blocks, campuses and hospitals.

Both self-contained and central battery emergency lighting can be “maintained” or “non-maintained.”

What is Maintained and Non-maintained in Relation to Emergency Lighting?

- A maintained emergency lighting fixture works as a normal lighting fixture when mains power is available and remains illuminated (usually at a reduced output level) using battery power when mains power fails. Typical examples of maintained emergency light fittings would include:

- LED panel and LED downlight conversions. These fittings are widely used in offices, classrooms and corridors. In a typical installation 1 in every 5-10 panels or downlights would be a maintained emergency conversion. This means that it is a standard panel or downlight to which an emergency conversion pack has been added, so that it looks and operates as a standard fitting but remains on (usually at a reduced output level) when mains power fails.

A typical LED panel. When installed along with the emergency conversion kit (pictured above) this becomes a maintained emergency light fitting.

When mains power is available it can be switched on and off as normal, but if mains power fails it automatically switches on at a reduced output level using its batteries, and can remain illuminated for at least 3 hours.

The plastic enclosure contains the necessary electronics and the batteries to power the fitting for 3 hours.

- Exit signs. These are often installed as maintained fittings, so that they are fully illuminated when mains power is available, and remain illuminated using battery power when mains power fails.

A typical exit sign. These are often installed to operate as maintained fittings, so they are on when mains power is available and remain on (using their battery power) if mains power fails.

- A non-maintained emergency lighting fixture is off when mains power is available and switches on, using battery power, when the mains power fails. Typical examples of a non-maintained fittings include:

- LED bulkheads. These are popular along escape routes and over doorways and are most often installed as non-maintained fittings. They illuminate only when mains power fails.

- LED twinspots. These are widely used in industrial and warehouse premises. They are almost always installed as non-maintained fittings that illuminate only when mains power fails.

Typical bulkhead and twinspot emergency light fittings. These are almost always installed as non-maintained fittings, so they only illuminate when there is a power failure.

Classified according to their function there are three main types of emergency lighting:

- Escape lighting. This is lighting whose function is to enable people to leave a building safely in the event of a power failure. Because of its importance to the safety of people in buildings escape lighting is closely regulated. Escape lighting can be subdivided into two types:

- Open area emergency lighting. The function of open area emergency lighting is to provide sufficient light to minimize the risk of panic and to enable the occupants of a building to reach and proceed along an escape route. Open area emergency lighting will typically be used throughout a building, both, for example, in a classroom or office and along a corridor or designated escape route.

- Emergency signage. The function of emergency signage is to show where an escape route is and to guide people along it by indicating changes of direction, for example, at the junction of two corridors or at the top of a flight of stairs.

- Standby lighting. This is lighting whose function is to enable existing tasks or activities to proceed uninterrupted by a power failure. For example, the lighting in a hospital operating theatre, a police incident room or the control centre in a power station would be equipped with standby lighting. Standby lighting is not a legal requirement and if it is needed or not will depend on the activities being carried out and the decisions of the building owners or occupiers.

- High risk task lighting. This is lighting whose function is to illuminate an area where a potentially hazardous task is being carried out for sufficiently long after a mains power failure for the task to be made safe prior to evacuation.